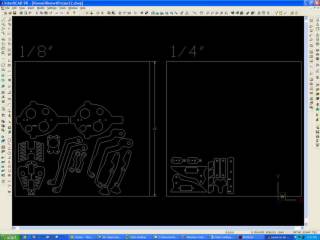

Laser Cut Parts Arrive

Outline files

The activities this week are to test the variables saving features of the ServoMojo board. This includes trim or centering, home position, acceleraion and speed, etc. Also, I'm putting togeather a spreadsheet to store servo locations for all the general motions required. This includes stand, sit, turn R / L, walk forward / back / arc, and transitions between all of the above.

All of these should be easily settable using either narrow or wide mode. Have you settled on which mode you will be using, or perhaps are you using a combination of the two modes?

One way to move to the "home" position is to generate a reset, which will cause the saved positions to be reloaded. Note, though, that the servos will snap back to their home positions as fast as they can at that time. This is due to not being able to know the actual servo positions at reset time. I could easily implement a "Home" command, though, that moves all the servos to their saved positions, without having to perform a reset, which also implies about a 3 second delay as the stored configuration is loaded from the on-board EEPROM. That command would allow the servos to be positioned and also honor the current velocity and acceleration settings, and eliminate the startup delay following a reset. The firmware you have does not support that - but it should be easy to add. I can send you a new chip that you can replace on the board to have that feature. The processor is in a socket to the replacement should be straight-forward.

There's a sample of how the Japanese guys do it here...

http://www.sozbots.com/robo-one/downloads/SoftwareManualEnglish.pdf

Unfortunately, I cannot find a description of the RCB-1's communication protocol in either the software nor the hardware documentation. Without that, I cannot say how easy or difficult it

would be to match it. However, their PC side software is similar to what I envision for ServoMojo. But I don't expect to have that piece in place for some time. I do think it is an important component, and one that I plan to have in place before I present the ServoMojo board for general availability. One hold-up for me has been the lack of a PC virtual machine that runs on my G5 Mac in order to do the development - the current version of Virtual PC supports up to the G4 processor, but not the G5. Just starting recently, however, Microsoft has begun taking pre-orders for the latest version of Virtual PC which finally supports the G5, so at least there is light at the end of the tunnel - but they still don't say exactly when it will be available.

-Brian

I ordered parts from Pololu in polycarbonate as a test of the material and the service. The Pololu laser cutting service is very inexpensive and their operator Jan Malasek is very helpfull and conscientious. http://www.pololu.com/laser_cutting.html

Not so much can be said about the aluminum watter cutting service DC waterjet.

Pololu can't cut metal nor mat'l thicker than 3/16". So I only sent them the parts that were 2D and 1/8" thick. Their charge for these parts was $28, and that includes the polycarbonate material, checking the file for errors and getting back to me on fixing them...I really like using them. I've not yet ordered the parts for the 1/4" material. Stuart is considering making them locally so we'll have one all aluminum bot and another plastic/aluminum hybrid.

The same parts cut in aluminum from DC water jet is $90. The 1/4" parts are $114. (not including material) Emachineshop.com was $118. All the 1/4" parts require extra machining after cutting out the outline.

Comments