The Finer Points of Surplus Parts

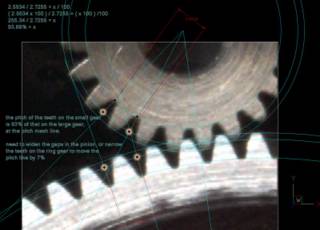

7% difference in the pitch of the surplus gears I've scrounged up for the build

Keith Rowell Design

We can always fix this gear problem with other answers if they fail to please.

I've deduced from the high res scans that there's a 7% difference in the pitch. I wondered if just "running them in" with a drill motor and a jig to apply preassure, or such, would "wear" them down to fit enough to make up that meager 7%. Ultimately either the gaps in the pinion teeth are too narrow or the teeth on the ring gear are too wide, or both. I believe that 7 percent will be an easy modification to reach, because even the slightest wear moves the pitch line alot. Maybe running them on a jig with lapping compound in their teeth would match them up...(I must sound like a real hill billy!)

what do you think?

Keith,

Is this a regular discussion in hill billy circles?

Don’t worry about the gears I think we can use them as they are.

See you later

Stuart

Keith,

The percentage of difference you're test shows suggests you have one metric and one fractional gear. Metric is measured in "Modules" and fractional is measured in "pitch".

Dale

Comments